Issue first then insert the tappets into their bores. click here for more details on the download manual…..

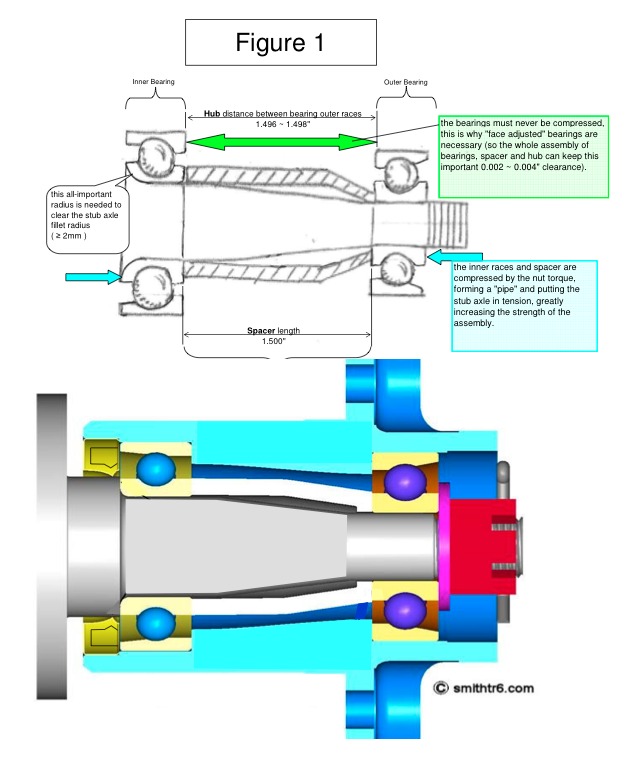

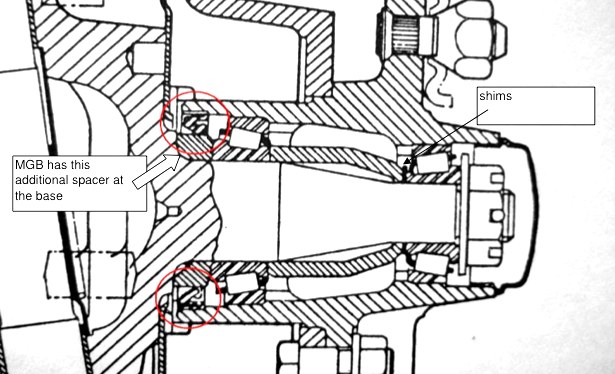

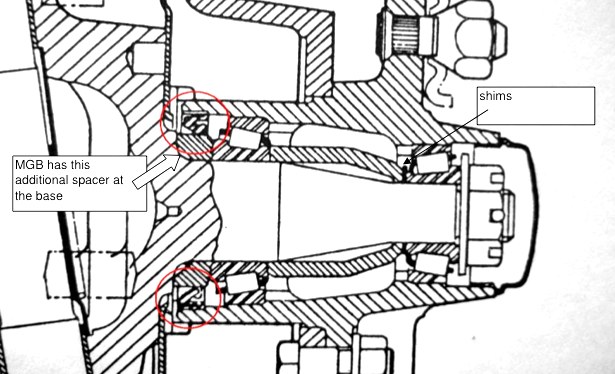

- Stub Axle Rebuild With Tapered Roller Bearings, Sprite & Midget In this video, Brendan from Spridget Mania rebuilds the front stub axles and brakes on Sprites & Midgets using Timken tapered roller bearings and shimming …

If you reuse the valve tappets make sure that they are reinstalled in their original bores. Install the woodruff key

If you reuse the valve tappets make sure that they are reinstalled in their original bores. Install the woodruff key

!

!

Disclosure of Material Connection: Some of the links in the post above are ‘affiliate links.’ This means if you click on the link and purchase the item, we will receive an affiliate commission. We are disclosing this in accordance with the Federal Trade Commissions 16 CFR, Part 255: ‘Guides Concerning the Use of Endorsements and Testimonials in Advertising.’